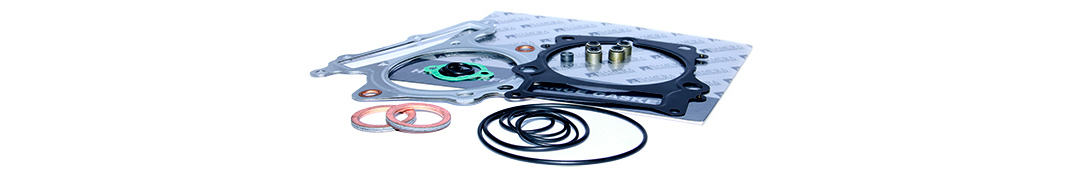

Q uality materials mean increased longevity and continued performance. A critical aspect of any rebuild, gaskets are often given little thought. However, the right materials can make all the difference.

We do all of the thinking, so you don’t have to. Our gaskets are manufactured from materials specifically chosen for each individual application. From top-end sets to complete kits for a full teardown, you can be sure that Namura gaskets are up to the task at hand.

Namura gaskets are manufactured to OE-specs, which means no trimming or fitment issues. Our materials are explicitly selected for their temperature, oil, fuel, and coolant-resistant qualities as well as tested using ASTM standards. Each design is evaluated against rigid quality-control standards to ensure each set meets or exceeds OE performance. Clutch gaskets are available for certain applications.

AF Gasket Material

Made from a high-quality, non-asbestos cellulose fiber composite bonded with Nitrile Butadiene rubber (NBR), this gasket material is ideal for clutch covers, oil pumps, coolant systems, and other engine case applications. It maintains excellent tensile strength, sealing integrity, and torque retention—even in continuous temperatures exceeding 300ºF.

Engineered for durability, it offers reliable performance in high-stress environments where fluid resistance and heat tolerance are essential.

Steel & MLS (Multi-Layer Steel) Gaskets

No other gasket is more crucial than your head gasket. The seal between your cylinder and cylinder head is exposed to more heat and extreme pressures than anywhere else in your engine. In order to match these extreme conditions we offer one of the most advanced head gaskets on the market. Constructed from multiple layers of stainless steel to resist corrosion and erosive chemicals commonly found in your engine, then using an on-off pattern, our MLS gaskets are coated/embossed with a Fluoroelastomer based rubber to tightly seal the metallic mating surfaces. By doing this they can withstand the sheering forces created by the two surfaces (cylinder head and cylinder). This coating also enhances the bond between the gasket material and the imperfect surfaces commonly found when rebuilding your engine.

Seals & O-rings

NBR, Fluoroviton, and Silicone are selected for each application based upon the following characteristics: Temperature Resistance, Abrasion Resistance, Chemical Resistance, and their Aniline Point. A Teflon coating is applied on certain applications to prolong performance life.

Namura Video

Namura Video Part Finder

Part Finder